Choosing the ideal Industrial Paint Booth is crucial for maintaining operational efficiency and ensuring workplace safety. The right booth enhances productivity by streamlining painting processes and delivering consistent, high-quality finishes. It also helps you comply with safety and environmental regulations, reducing risks and potential penalties. A well-suited paint booth minimizes long-term costs by improving energy efficiency and reducing maintenance needs. By selecting the right booth, you create a safer, more efficient workspace while achieving superior results for your facility.

Types of Paint Booths

Choosing the right type of paint booth is essential for achieving optimal results in your facility. Each type offers unique features and benefits tailored to specific operational needs. Understanding these differences helps you select the most suitable option.

Cross Draft Paint Booths

Cross draft paint booths provide a straightforward airflow design. Air enters through filters at one end and exits through exhaust filters at the opposite end. This design ensures consistent airflow across the workspace. These booths are cost-effective and easy to install, making them a popular choice for facilities with limited budgets.

However, cross draft booths may not deliver the same level of finish quality as other types. The airflow can sometimes cause overspray to settle unevenly on surfaces. This limitation makes them less ideal for operations requiring precision finishes. If your facility handles high-volume or basic painting tasks, this booth type can meet your needs effectively.

Semi Down Draft Paint Booths

Semi down draft paint booths combine elements of cross draft and down draft designs. Air enters from the ceiling near the front of the booth and exits through exhaust filters along the floor or walls. This setup improves airflow control compared to cross draft booths. It reduces overspray and enhances the quality of finishes.

These booths strike a balance between performance and cost. They are more affordable than full down draft booths while offering better results than cross draft options. However, they may not provide the uniform airflow required for highly detailed or complex finishes. For mid-range painting operations, semi down draft booths offer a practical solution.

Full Down Draft Paint Booths

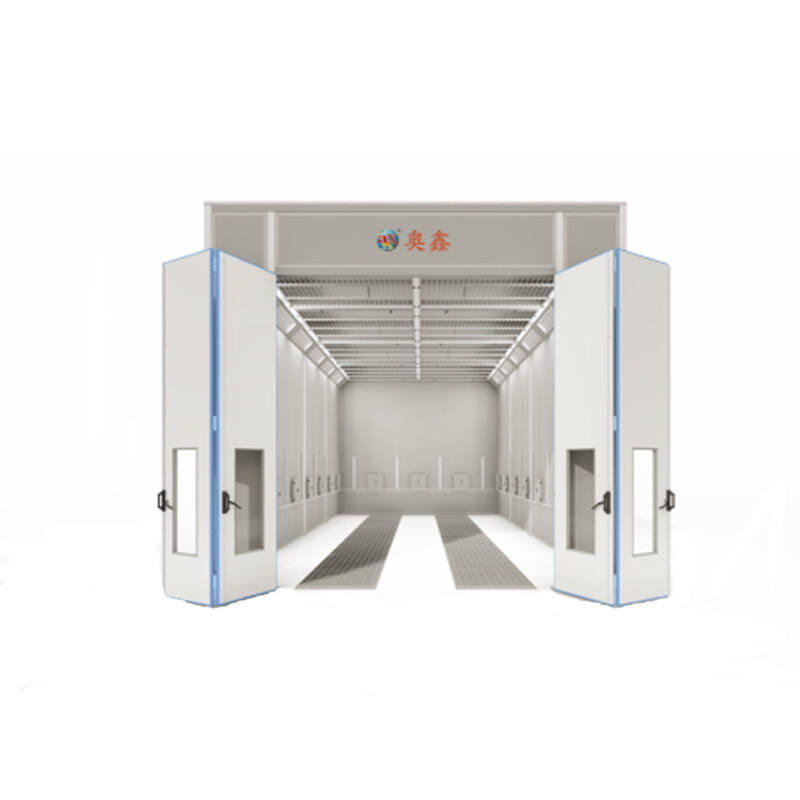

Full down draft paint booths deliver the highest quality finishes. Air flows vertically from the ceiling to the floor, enveloping the painted object completely. This design minimizes overspray and ensures even coating application. These booths are ideal for industries requiring precision, such as automotive or aerospace manufacturing.

The advanced features of full down draft booths come with higher costs. Installation requires more space and resources, and operational expenses can be significant. Despite these challenges, the superior results justify the investment for facilities prioritizing quality. If your goal is to achieve professional-grade finishes, this booth type is the ideal industrial paint booth for your needs.

Side Down Draft Paint Booths

Side down draft paint booths offer a distinct airflow design that enhances painting efficiency. Air enters the booth through filters located in the ceiling and flows downward at an angle toward exhaust vents positioned along the sides of the booth. This setup creates a controlled environment that minimizes overspray and ensures even coating application.

One of the key benefits of side down draft booths is their ability to provide consistent airflow without requiring a fully downdraft system. This makes them a practical choice for facilities that need high-quality finishes but have limited budgets or space constraints. The side exhaust vents help capture overspray effectively, reducing contamination and improving the overall quality of the painted surface.

Key Features of an Ideal Industrial Paint Booth

When selecting filters, you should consider the specific needs of your operations. Primary filters capture larger particles, while secondary filters handle finer contaminants. High-efficiency filters, such as HEPA filters, are ideal for facilities requiring precision finishes. Regularly replacing filters keeps the system functioning effectively and prevents airflow blockages. A well-maintained filtration system ensures your ideal industrial paint booth operates at peak performance.

A temperature-controlled paint booth allows you to maintain the ideal conditions for your operations. Heating systems ensure consistent warmth, even in colder environments. Advanced booths may include programmable controls, enabling you to set precise temperature levels for different projects. By prioritizing temperature stability, you enhance the quality of your finishes and reduce the likelihood of rework.

Compliance and Safety Standards

Fire safety is a critical consideration for any industrial paint booth. The use of flammable materials increases the risk of fires, making it essential to implement robust fire suppression systems. Install automatic fire sprinklers or chemical suppression systems to quickly extinguish flames in case of an emergency. Regularly inspect and maintain these systems to ensure they function effectively.

Protecting workers should always be a top priority in your facility. Personal protective equipment (PPE) plays a vital role in safeguarding employees from potential hazards. Provide workers with respirators, gloves, goggles, and protective clothing to shield them from harmful chemicals and airborne particles. Ensure all PPE meets industry standards and fits properly for maximum effectiveness.

Conclusion

Choosing the ideal industrial paint booth requires a clear understanding of your facility's needs. Evaluating booth types ensures you select one that aligns with your operational goals. Considering key features like filtration, lighting, and temperature control enhances efficiency and quality. Compliance with safety standards and careful cost planning protect your investment and workers. Take the time to assess your options thoroughly. Consult industry experts to make an informed decision. The right choice will improve productivity, ensure safety, and deliver long-term value for your facility.