Industrial paint booths provide a controlled environment for painting processes. You can rely on them to manage environmental factors like airflow and temperature. These booths reduce contamination risks and improve paint application. By using industrial paint booths, you ensure consistent results while meeting quality standards in your production line.

What Are Industrial Paint Booths?

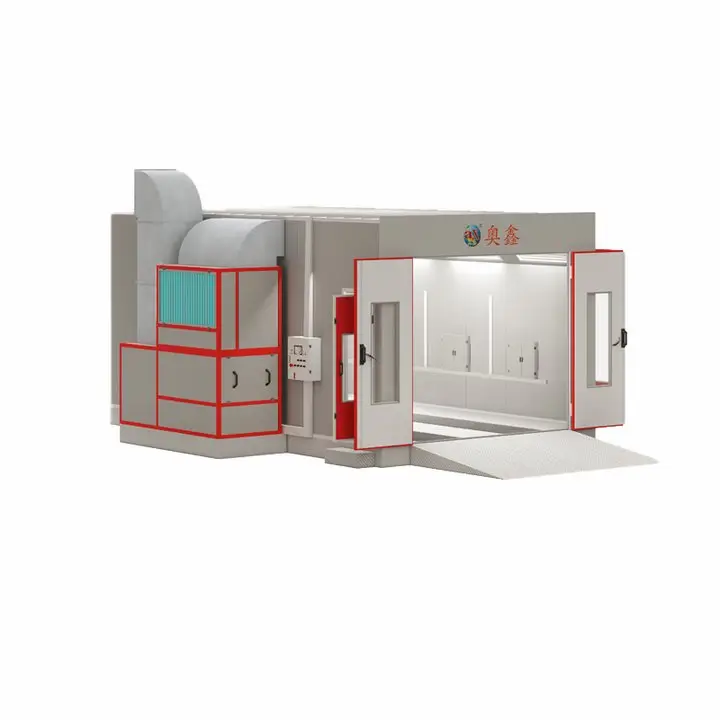

Industrial paint booths are specialized enclosures designed to create a controlled environment for painting processes. These booths help you manage factors like airflow, temperature, and contaminants. By using them, you can achieve consistent, high-quality finishes while reducing the risk of defects. Their primary purpose is to ensure that painted surfaces meet industry standards for durability and appearance. Additionally, they protect workers by containing hazardous fumes and overspray.

You can find several types of industrial paint booths, each designed for specific applications. Some common types include:

- Crossdraft Booths: These booths pull air horizontally across the workspace, making them cost-effective for basic painting needs.

- Downdraft Booths: Air flows vertically from the ceiling to the floor, ensuring minimal contamination.

- Side Downdraft Booths: These combine horizontal and vertical airflow for better overspray control.

- Open-Face Booths: These are ideal for smaller projects, as they have an open front and exhaust air through the back.

- Custom Booths: Tailored to meet unique requirements, these booths offer flexibility for specialized industries.

Features That Enhance Quality Control

Airflow Management

Proper airflow management is one of the most critical features of industrial paint booths. It ensures that air moves consistently throughout the booth, carrying away overspray and fumes. This prevents uneven paint application and contamination. You’ll find that different airflow designs, such as crossdraft or downdraft systems, cater to specific needs. For example, downdraft systems direct air vertically, which minimizes the risk of particles settling on freshly painted surfaces. By maintaining controlled airflow, you can achieve a smooth, professional finish every time.

Temperature and Humidity Control

Temperature and humidity play a significant role in the quality of paint application. Industrial paint booths often include systems to regulate these factors. When the temperature is too low, paint may not cure properly. High humidity can cause defects like bubbling or uneven drying. By controlling these variables, you ensure that the paint adheres correctly and dries uniformly. This feature is especially important for industries requiring precise finishes, such as automotive or aerospace manufacturing.

Filtration Systems for Contaminant Prevention

Filtration systems are essential for keeping contaminants out of the painting environment. These systems trap dust, debris, and other particles before they can settle on painted surfaces. Most industrial paint booths use multi-stage filters to capture both large and microscopic particles. Clean filters ensure that the air inside the booth remains pure, which reduces the risk of defects. You should replace filters regularly to maintain optimal performance and protect the quality of your work.

Ensuring Compliance with Standards

You must ensure that your painting processes comply with environmental regulations. Industrial paint booths help you meet these requirements by controlling emissions and capturing hazardous particles. Many booths include advanced filtration systems that reduce volatile organic compounds (VOCs) released into the air. This protects the environment and keeps your operations within legal limits. You should also monitor waste disposal practices. Properly disposing of paint waste prevents contamination of soil and water sources. Staying compliant with environmental laws not only avoids penalties but also demonstrates your commitment to sustainability.

Industrial paint booths are designed to protect workers and maintain a safe workspace. These booths contain harmful fumes and overspray, reducing exposure to toxic chemicals. Many models include fire suppression systems to prevent accidents caused by flammable materials. You should also ensure proper ventilation to minimize the risk of inhaling hazardous substances. Providing employees with personal protective equipment (PPE) adds an extra layer of safety. Following safety standards not only protects your team but also reduces the likelihood of costly workplace incidents.

Meeting certification requirements enhances your credibility and ensures product quality. Many industries require you to use certified equipment, including industrial paint booths, to meet specific standards. For example, automotive and aerospace sectors often demand compliance with ISO or other industry-specific certifications. Regular inspections and maintenance help you keep your equipment in top condition, ensuring it meets these standards. Certification not only boosts customer confidence but also opens doors to new business opportunities.

Conclusion

Industrial paint booths help you maintain quality control by creating controlled environments. They prevent defects and ensure compliance with industry standards. These booths improve operational efficiency and deliver consistent, high-quality finishes. Investing in them enhances your production processes and ensures your products meet the highest expectations in competitive markets.